Hydrocracking Catalyst for Maximum Production of Clean Diesel with Low Freezing Point

1. Introduction

Hydrocracking catalyst LSFC-20 comprises W and Ni as hydrogenation components and molecular sieves as cracking component. The catalyst features Y-type zeolite cracking component. LSFC-20 catalyst has excellent catalytic activity, high diesel selectivity, good stability, high strength, etc, and can be used to obtain a wide range of high quality middle distillates with long-term stable operation.

2. Catalytic activity

(1) Operation conditions: Reaction pressure over 10.0 Mpa, H2/oil ratio over 800:1, LHSV 1.5 h-1, and initial inlet air temperature 375 to 410 degree celsius.

(2) Feedstocks: light diesel oil and heavy diesel oil, coker diesel oil, and crude distillation wax oil.

(3) Product: residual oil yield≤ 20%, liquid yield ≥ 97%, diesel S<10PPm

3. Application

This catalyst has been applied in hydrocracking unit with a capacity of 1.2 million t/a in Daqing Petrochemical Company.

| Items | Physical and Chemical Properties |

| Chemical composition | WO3-NiO/Al2O3-SiO2 |

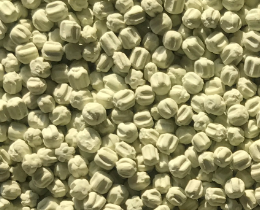

| Form | Denti-ball |

| MoO3 content m%, | 21~24 |

| NiO content m% | 6.2~7.8 |

| Diameter, mm | 2.2~2.6 |

| Bulky density, kg/m3 | 0.85~0.95 |

| Specific area, m2/g | >200 |

| Crushing strength, N/p | ≥30 |

| Attrition, % | ≤2.0 |